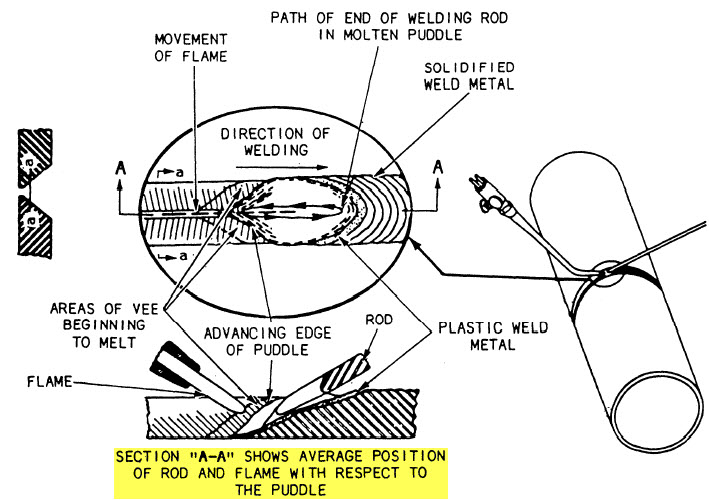

Keep in mind during the welding process it is important to direct the arc right at the center of the weld puddle and don t do movements like whipping or weaving as it may cause warping and burn through quickly.

How to tig weld sheet metal without warping dvd.

Learn why mig pulsed mig tig and pulsed tig are the ideal choices when welding sheet metal.

If you re welding thinner materials like automotive sheet metal it is more critical that you keep the heat to a minimum when welding.

This restraint creates high residual tensile stress that causes the weld to act like a stretched rubber band with the workpiece holding the ends figure 1 for this reason when the clamps that hold the workpiece are removed the base metal is allowed to move or spring.

Tig welding is an excellent example of the less is more premise producing strength without adding mass and mess.

Tack welds stitch welds then.

The best two electrodes for welding auto body sheet metal is either ceriated tungsten or thoriated tungsten.

When welding thin metal the main objective is to avoid warping burn through and excessive heat affected zones while still ensuring the weld has enough mechanical strength for the application.

When mig welding sheet metal it is important to set the proper parameters to prevent warping and burn through or else it will create excess heat and easily blowholes on the metal.

When welding steel this weld bead is laid down at around 2 500 f 1 370c.

Arc welding mig and tig entails fusing a filler metal with the materials being joined.

October 4 2019 by.

In this video i did a bunch of weld tests on sheet metal to see how much it would warp by the different styles of mig welding.

Then as the bead cools and solidifies it contracts but by this time the metal pieces are fused together.

How to weld auto body sheet metal with a tig welder.

That heat spreads out making the metal expand.

Tig welding is preferred where practical because it is neater and cleaner than mig welding which introduces new material into the weld joint.

Top ways to keep metal from warping when welding.

Ditch a 1 8 inch tungsten electrode for something much smaller like 1 16 inch tungsten.